Fire Protection and Detection System

Fire detection systems serve a simple purpose to spot fires early enough to allow for the safe evacuation of personnel and, if possible, for a quick response to put the fire out. With the right fire detection system, the human and equipment costs due to damage can be significantly reduced. Electronic detection systems usually use alarms to quickly alert people nearby or connected to a monitoring system. . This provides warning of a fire to building occupants and can provide information to emergency responders on the location of the fire, speeding the process to control the fire, and a fire protection system aims to protect a building’s occupants while minimizing the damage associated with fire. Overall, the goal is to provide the widest possible window for a safe evacuation and reduced damage to equipment, which will lessen downtime and potential repair costs.

Fire Protection and Detection System : Benefits

By having a comprehensive fire protection and detection system list, building owners and managers can help improve their buildings’ fire safety and protect their people and property.

- A building manager can use the list to ensure all fire detectors are installed, maintained, and tested regularly.

- A business owner can use the list to develop a fire safety plan that includes procedures for evacuating the building safely in the event of a fire.

- A safety officer can use the list to train employees on using the fire alarm system and fire extinguishers.

By using a fire protection and detection system list, building owners, managers, and safety officers can help to create a safer environment for everyone. Here’s a couple of specific fire equipment lists:

DIESEL ENGINE-DRIVEN FIRE PUMP SYSTEM

A reliable system depends on design considerations such as fuel supply, combustion air, exhaust, ventilation, and engine cooling. A fire pump can be driven by an electric motor, diesel engine, or steam drive. While electric motors are most common, steam drives are infrequently utilized. Diesel engines are often used when the electrical supply to the property is unreliable or has insufficient capacity. Clients use these systems when they prefer a primary electric motor-driven fire pump system and a redundant diesel engine-driven fire pump system. Alternatively, they may opt for these systems in properties that necessitate a redundant setup, either due to seismic considerations or the building’s height.

This column will discuss design and installation issues with a diesel engine-driven fire pump system. Diesel engines have been used in light- and heavy-duty applications for decades. A diesel engine driver is commonplace for larger generator sets. While a generator set and fire pump system might use similar diesel engines, their design and installation in certain vital areas are drastically different.

ELECTRIC-DRIVEN FIRE PUMP

These are control panels containing electrical components such as circuit breakers, switches, relays, and other devices dedicated to the operation of fire pumps.

The Electrical Motor Driven Main Pump’s function is to START automatically when a hydrant valve or sprinkler is activated and to provide adequate water under pressure to the system.The capacity of the pump will differ, basis the size of the system. The pump is stopped manually.

JOCKEY PUMP

On a fire protection system requiring a fire pump, there is a small pump that maintains pressure above the pressure settings of the larger fire pump. Hence the name “jockey pump.” The purpose of a jockey pump is to maintain pressure in a fire protection piping system so the larger fire pump does not need to run.

This small apparatus works alongside a fire pump to offer a complete fire-protection sprinkler system. It can help keep the pressure elevated to a specific level when you are not using the system. This means that the system does not go off randomly, but the fire pump does not have to run all the time andthe jockey pump pressure should be about 10 psi (0.7 bar) higher than the booster pump pressure. So, the jockey pump shutoff pressure should be 27.5 psi + 10 psi = 37.5 psi (1.9 bar + 0.7 bar = 2.6 bar)

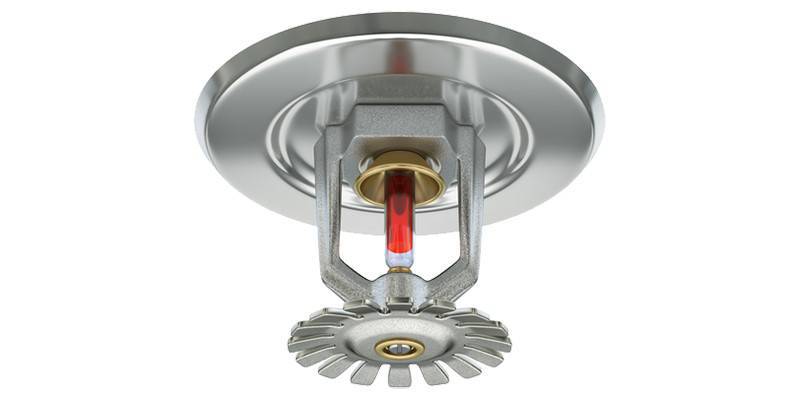

SPRINKLER

A fire sprinkler system is an active fire protection method, consisting of a water supply system, providing adequate pressure and flow rate to a water distribution piping system, onto which fire sprinklers are connected. Although historically only used in factories and large commercial buildings, systems for homes and small buildings are now available at a cost-effective price.

HOSE RACK CABINET

The fire hose reel cabinet protects the fire hose reel from contamination & damage. The cabinet is surface or recess mounted in a wall, with a compact design for saving space and easy access for operation.

To operate a fire hose reel, turn water onto the hose reel by operating the control valve remove the nozzle from its bracket proceed to a safe distance from the fire.

HOSE RACK SET

Hose Rack Assemblies permit readily available means of controlling and suppressing fire by one person. The semiautomatic swing rack with movable pins features an automatic release mechanism, keeping water out of the hose (when the valve is open) until the last fold is released.

LANDING VALVE

Landing valves were used to describe fire service valves provided on Risers in buildings, as these were typically located in Staircase landings to allow easy access to Fire Fighters.

6 Types of Flow Control Valves & What You Need to Know About Them

- Ball Valves

- Check Valves

- Butterfly Valves

- Gate Valves

- Globe Valves

- Needle Valves

PILLAR HYDRANT UNIT

A pillar hydrant is a permanently installed above-ground fitting used for the withdrawal of extinguishing water. The pillar hydrant has various outlets (A, B, or C) based on several couplings and is only used by the fire brigade.For most intents and purposes, there are two types, wet and dry barrel hydrants, and standpipes. These have different structures and mechanisms depending on the surrounding conditions.

A pillar hydrant is a permanently installed above-ground fitting used for the withdrawal of extinguishing water. The pillar hydrant has various outlets (A, B, or C) based on several couplings and is only used by the fire brigade.For most intents and purposes, there are two types, wet and dry barrel hydrants, and standpipes. These have different structures and mechanisms depending on the surrounding conditions.

FIRE HYDRANTS COMPONENTS:

- Fire Fighting Pumps & Accessories

- Piping

- Panels Landing Valves

- Hoses

- Couplings

- Hose Reel Branch

- Pipes & Nozzles

4 WAY BREECHING INLET

Breeching inlets are installed outside the building or in any easily accessible area in the building for fire brigade personnel to access the inlet. This inlet is used by fire brigade personnel to access water. It is normally dry but is used to pump water by charging using firefighting equipment.

The height requirement for breeching inlet mains needs to be charged with water through the breeching inlets by fire engines. The dry rising mains should not exceed 60m in height to avoid excessive pumping pressure.

Fire Door

A fire door is a fire-resistance rating that is used as part of a passive fire protection system to reduce the spread of fire and smoke between compartments of a structure and to allow safe egress from a building, or structure.

The main functions of fire doors are:

- To allow egress from space and to close once released.

- Protect escape routes from the effects of fire (smoke, gases, and flames)

- Potentially limit the amount of oxygen available and slow the growth of a fire.

The most authentic way to identify a fire door is to check its certification label. All fire doors are required to have a certification label as it acts as proof of whether the doors are tested enough to determine their fire resistance level. These labels are usually found on the top edge of the door leaf.

VALVES & ACCESSORIES

FLEXIBLE JOINT

Flexible joint is a coupling that can transmit torque between two shafts that are not aligned. A flexible joint between the shafts corrects any misalignment. A flexible joint allows some movement between the steering shaft and the steering box.

CHECK VALVE

Check valves are generally installed in pipelines to prevent backflow. A check valve is basically a one-way valve, in which the flow can run freely one way, but if the flow turns, the valve will close to protect the piping, other valves, pumps etc.Most common types of Check valves are swing, lift (piston and ball), butterfly, stop and tilting-disk.

OS & Y GATE VALVE

NRS means Non-Rising Stem. OS&Y means Outside Stem and Yoke. In an NRS valve, the stem will turn to open and close the gate, but the stem does not move up or down as it turns. With an OS&Y valve, as the stem turns, it moves into or out of the valve, which also moves the gate to open or seal the valve. An OS&Y valve is open when the threaded stem extends from the valve. The valve is closed when the stem is not visible above the control wheel.

Y-STRAINER

To provide for easier maintenance, the Y-Strainer should be located where the drain plug can be removed. Additionally, ensure the drain or blow-off is located at the lowest position when installed. If installed in the vertical position, the wye side of the strainer must be pointing downward.

PRESSURE RELIEF VALVE

Pressure relief valves (safety relief valves) are designed to open at a preset pressure and discharge fluid until pressure drops to acceptable levels. The three basic types of pressure-relief valves are conventional spring-loaded, balanced spring-loaded, and the pilot operated.

BALL VALVE

A ball valve is a shut off valve that controls the flow of a liquid or gas by means of a rotary ball having a bore. By rotating the ball a quarter turn (90 degrees) around its axis, the medium can flow through or is blocked. They are characterized by a long service life and provide a reliable sealing over the life span, even when the valve is not in use for a long time. As a result, they are more popular as a shut-off valve then for example the gate valve. In special versions, ball valves are also used as a control valve. This application is less common due to the relatively limited accuracy of controlling the flow rate in comparison with other types of control valves. However, the valve also offers some advantages here. For example, it still ensures a reliable sealing, even in the case of dirty media. Figure 1 shows a sectional view of a ball valve.

WATER FLOW METER

A High-performance electromagnetic flowmeter accurately measures the flow volume of any conductive liquids, such as water, salt water, sewage, pulps, slurry, acid, any mixtures of liquids and solids which have a specific minimum of 5μS/cm of electrical conductivity. Our Clients has been widely used in municipal, wastewater treatment, irrigation, chemicals, as well as industrial liquid processes.

PRESSURE GAUGE

A device that uses the surface area and weight of a liquid column to measure and indicate pressure is known as a manometer. Most gauges calculate the pressure relative to atmospheric pressure as the zero point. Hence, this form of reading is known as gauge pressure. Pressure gauges are analog as well as digital. Four types of pressure measurements are gauge, sealed, absolute and differential.

SUPERVISORY SWITCH

Supervisory switches detect the status of a fire sprinkler system and relay that information to a central, proprietary, or remote monitoring center or sound a local alarm. It is a mechanical and electrical device connected to a fire protection valve that signals a warning if the valve partially or fully closes.

AUTO AIR VENT VALVE

The device consists of a polypropylene float connected to a simple valve. When the build-up of air within the float chamber exceeds a certain level the float drops, opening the valve and releasing the air trapped within the chamber. You can use it anywhere where there’s a need for air removal from pipes.

WATER FLOW SWITCH

A water flow detector, also known as a flow switch, is an electro-mechanical device designed to send an alarm to a monitored panel and/or fire department when a continuous flow of water occurs through a fire sprinkler system’s piping. This flow signifies an activated sprinkler head or a leak in the system.Flow switches help maintain safe and manageable rates of flow by triggering actions in various machines within a system to provide on/off flow control.

ZONE CONTROL VALVE

Zone Control Valve is a system designed to separate the area in case of maintenance and to get the indication of fire zone on a combination of Butterfly valve, Flow Switch, Pressure Gauge and Test & Drain Valves. Its main purpose it to regulate water flow in the designated “zones” or areas and in some buildings, by floors / levels, thus named zone control valve.

SEAMLESS/ERW MS PIPE

We are Supplier of Stainless Steel Pipe, MS Seamless Pipe Size range as per ANSI B36.10. Steel pipes are available in the market. They are divided into different grades and schedules.

Addressable Fire Alarm control panel :Fire Detection System

An addressable fire alarm system is one in which all fire and smoke detection devices in a system are connected and communicate both with each other and a central control monitoring location. This interconnectivity allows the control personnel to identify the location or “address” where the initial detection occurred. The information directs the emergency response team to pinpoint their efforts immediately to the precise location of the developing problem.

Addressable Smoke Detector

Find the source of problems faster, while simultaneously protecting occupants and property with our massive selection of addressable smoke detectors. Most smoke detector systems are equipped with their own fire alarm control panel making it difficult to locate which area of an establishment triggered the alarm, especially if multiple alarms are used in large buildings or areas. In this situation, addressable smoke detectors, also known as analog smoke detectors are the best type of detectors to use and pear perfect for large commercial buildings

The control panel of each addressable device is separated so it can be controlled by a central fire alarm panel. The setup of an addressable fire alarm system allows it to quickly identify which smoke detector device was individually activated. This means more issues can be detected, isolated, and resolved faster and more efficiently than any other type of smoke detector on the market. The critical information provided by addressable alarm systems allows firefighters to pinpoint the exact location of an alarm signal, which is very useful in managing an emergency, especially in a large building.

Addressable Multi-Detector

Addressable multi-sensor detector(s) are designed to work with Addressable panel. These detectors are low profile, polarity free, and have dual LED’s for 360° visual indications. The LED’s are blinking in normal operating condition whereas the LED’s in steady state indicate fire status. Multi-sensor detectors use a combination of more than one type of sensor – smoke, heat, or carbon monoxide – to detect the presence of a fire.

External Power Supply

Primary power to the fire alarm system can be provided by the electric utility, an engine-driven generator. Requires two External Power supplies for independent and reliable sources of power for fire alarm systems: a primary and a secondary source.

Addressable Heat Detector

Addressable Intelligent multisensory detector. This device is intended to be used for an addressable automatic fire detection system to detect the presence of smoke, smoke density, and abnormal temperature for fire alarms. Three types of heat detectors -Fixed-temperature detectors; Rate of rise detectors; Rate compensated; Combination rate of rise and fixed temperature.

Addressable Manual Call Point

If a fire is discovered before the fire alarm system is activated, the addressable manual call point allows occupants to trigger the system from a single location. As part of an addressable fire alarm system, each installed call point is assigned an “address”. This allows for authorized personnel to quickly identify the exact device that has been activated, and in turn saves time for the emergency services to locate the origin of the fire.

Addressable Beam Detector/ Conventional

A device which senses smoke by projecting a light beam from a transceiver unit across the protected area to a reflector that returns the light signal back to the transceiver unit. Smoke entering the beam path will decrease the light signal causing an alarm.There are two basic types of beam detector: End to End: Transmitter and receiver are mounted at either end of the protected area. Reflective: Transmitter and receiver are mounted in the same housing, and the beam is directed at a specially designed reflector, mounted at the opposite end of the protected area.

Conventional Sounder with flasher

A device which senses smoke by projecting a light beam from a transceiver unit across the protected area to a reflector that returns the light signal back to the transceiver unit. Smoke entering the beam path will decrease the light signal, causing a fire alarm sounder to activate and flash.

Input Module

In PLC, to take the input and to return the output, there are an I/O module. The input modules are used for providing an interface for input devices like different types of switches (push button switch, selector switch, limited switch), sensors. Input modules monitor devices responsible for alarm inputs and confirm signals or technical states etc. The input lines are monitored for open and short circuits. Addressable modules can be independently configured via a fire control panel for status or alarm messages.

Output Module

The purpose of a PLC Output module is to operate or control a physical device based on field device conditions connected to an input module and decisions made by the PLC program. PLC are divided into three types based on output namely Relay output, Transistor output, and Triac Output PLC. The relay output type is best suited for both AC and DC output devices.

Brand We offer-